Metalworking fluids (MWFs), also known as cutting fluids, are essential in the metalworking industry. They help reduce tool wear, improve machining efficiency, and protect equipment by lubricating and cooling the contact area between tools and workpieces.

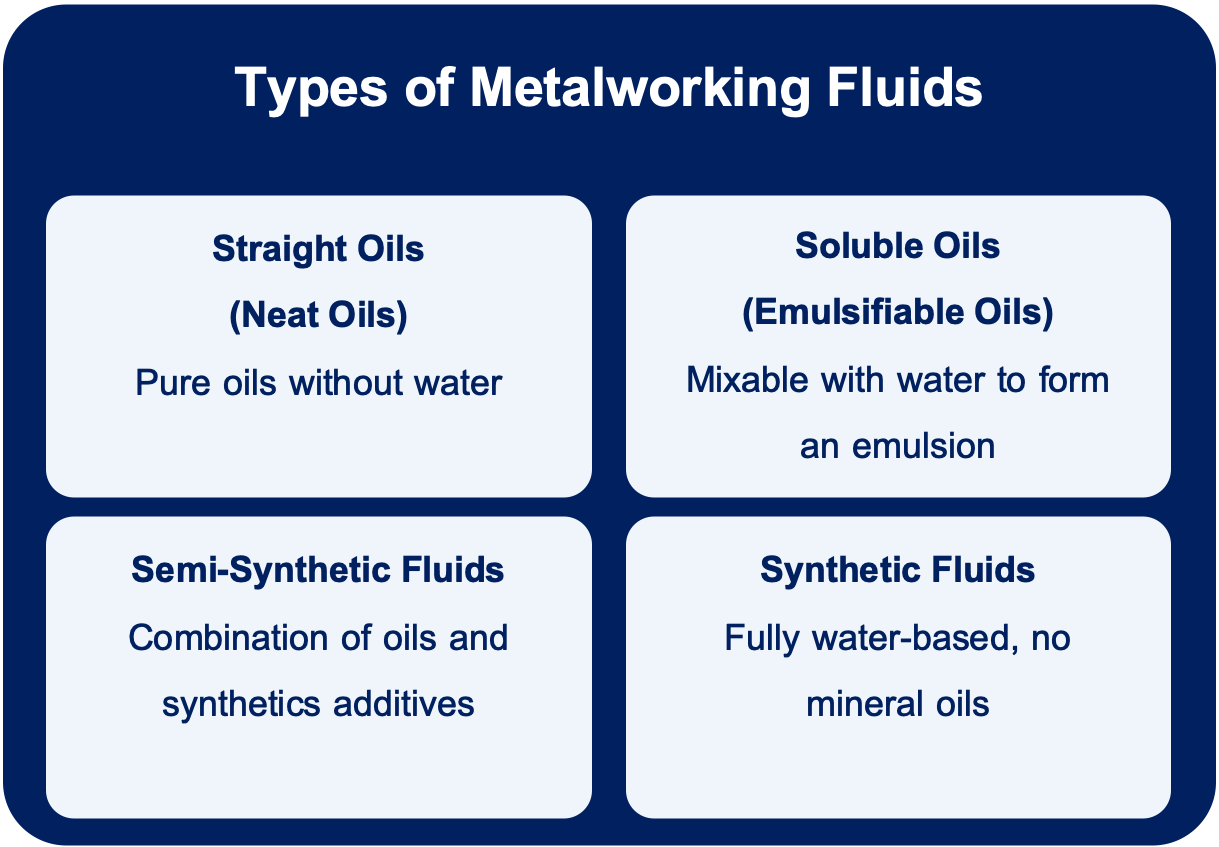

Types of Metalworking Fluids

1. Straight Oils (Neat Oils)

- Pure oils without water, such as mineral, vegetable, or synthetic oils

- Provide excellent lubrication, ideal for high-torque cutting

- Limited cooling effect, may generate localized heat

2. Soluble Oils (Emulsifiable Oils)

- Mixable with water to form an emulsion

- Offers balanced lubrication and cooling

- Suitable for general machining operations

3. Semi-Synthetic Fluids

- Combination of oils and synthetic additives

- Provides good lubrication and cooling

- Ideal for operations needing a balance between performance and efficiency

4. Synthetic Fluids

- Fully water-based, no mineral oils

- Excellent cooling properties, perfect for high-speed machining

- Reduces heat buildup and extends tool life

Why Choosing the Right MWF Matters

Using the correct metalworking fluid for the material and operation ensures:

- Better workpiece quality

- Longer tool life

- Lower production costs

- Enhanced safety and efficiency in the workshop

Selecting the right MWF is a small investment that can make a big difference in machining performance.